The Critical Role of Effective Ash and Slag Removal Systems in Boiler Island Operations

Efficient operation of a boiler island is critical for power plants, industrial facilities, and large-scale manufacturing plants. One of the most vital components in maintaining seamless performance is the ash and slag removal system of boiler island. This system not only ensures operational efficiency but also plays a key role in safety, environmental compliance, and cost management.

Understanding Ash and Slag in Boiler Operations

Boilers in thermal power plants and other industrial settings burn solid fuels like coal, biomass, or other materials to generate heat and steam. During combustion, residues such as ash and slag are produced. Ash is typically the fine, powdery material that remains after combustion, while slag is the molten or semi-molten residue that forms at high temperatures.

If these residues are not properly removed, they can accumulate in the boiler and associated equipment, leading to blockages, reduced heat transfer efficiency, and potential damage to the boiler’s structural components. This is where the ash and slag removal system of boiler island becomes indispensable.

Role of Efficient Ash and Slag Removal Systems

The primary role of an ash and slag removal system is to collect, transport, and dispose of ash and slag in a safe and efficient manner. An optimized system ensures continuous boiler operation without unscheduled shutdowns, which is critical for maintaining plant productivity.

Enhancing Operational Efficiency

Boilers operate at extremely high temperatures, and the accumulation of ash and slag can act as an insulating layer on heat transfer surfaces. This reduces the efficiency of heat transfer, requiring more fuel to achieve the desired steam output. By utilizing an effective ash and slag removal system of boiler island, plants can maintain optimal heat transfer, ensuring the boiler produces maximum output with minimum fuel consumption.

Minimizing Wear and Tear

Ash and slag contain abrasive materials that can damage boiler tubes, fans, and other critical components if not removed promptly. Efficient removal systems reduce the mechanical stress on these components, extending their service life and lowering maintenance costs.

Ensuring Safety

Accumulation of ash and slag can lead to dangerous operational conditions. Slag buildup, in particular, can result in blockages that create pressure imbalances, increasing the risk of boiler explosions or fires. The ash and slag removal system of boiler island mitigates these risks by continuously removing residues and maintaining proper boiler pressure and temperature levels.

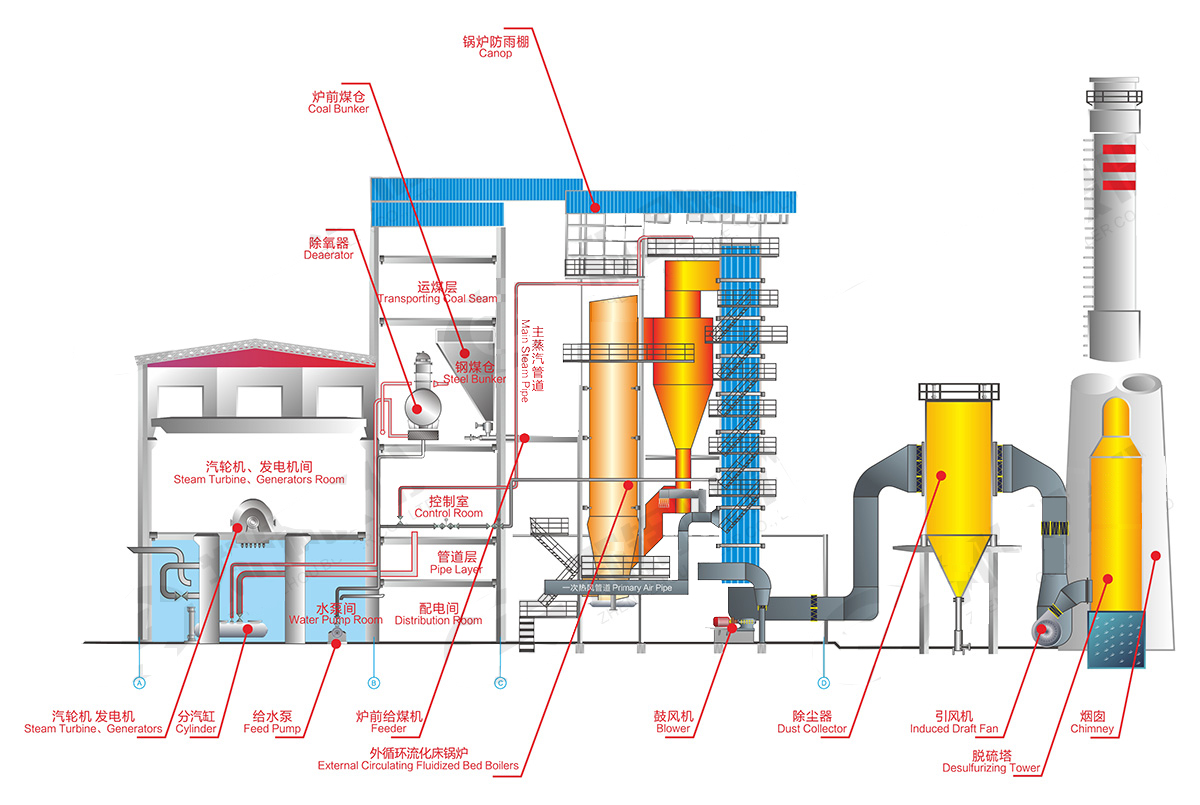

Components of an Effective Ash and Slag Removal System

An advanced ash and slag removal system typically includes mechanical, hydraulic, or pneumatic components designed for high-temperature environments. Key components include:

- Ash hoppers and chutes: These collect ash from different sections of the boiler.

- Slag tap systems: These allow molten slag to exit the boiler safely and solidify in a controlled manner.

- Conveying mechanisms: Systems such as screw conveyors, pneumatic conveyors, or water-based transport systems move ash and slag to storage or disposal points.

- Dust collection units: These filter fine ash particles from exhaust gases to reduce environmental emissions.

Integration of these components ensures that ash and slag are handled efficiently without interrupting boiler operation.

Environmental Benefits

Modern environmental regulations demand strict control of particulate emissions from industrial boilers. Ash and slag contain pollutants that, if released uncontrolled, can contribute to air and water contamination. An effective ash and slag removal system of boiler island helps plants meet these regulatory requirements by capturing residues at the source. Collected ash can also be repurposed in industries such as cement and construction, reducing waste disposal issues and promoting sustainability.

Maintenance and Monitoring

Regular inspection and maintenance of the ash and slag removal system of boiler island are critical to ensuring long-term performance. Monitoring systems can detect blockages, wear, and abnormal operating conditions, enabling predictive maintenance. This proactive approach reduces the risk of costly downtime and helps operators plan maintenance schedules more efficiently.

Cost Efficiency and Economic Impact

A well-designed ash and slag removal system directly impacts the economic efficiency of boiler operations. Reduced downtime, lower fuel consumption, and extended equipment life translate into significant cost savings. Additionally, proper management of residues can create revenue streams through the sale or reuse of ash and slag in various industrial applications.

Innovations in Ash and Slag Removal Technology

Technological advancements are enhancing the performance of ash and slag removal systems. Automated and remotely monitored systems allow operators to track residue levels in real-time and adjust operations accordingly. High-temperature resistant materials for conveyors and hoppers improve durability, while environmentally friendly disposal methods reduce the ecological footprint of boiler island operations.

Implementing these innovations ensures that the ash and slag removal system of boiler island remains efficient, safe, and compliant with modern industrial standards.

Conclusion

The efficiency and safety of boiler island operations are heavily dependent on an effective ash and slag removal system of boiler island. By ensuring proper residue management, plants can maintain high operational efficiency, reduce maintenance costs, comply with environmental standards, and promote sustainable practices.

Investing in advanced ash and slag removal technology is not just a matter of regulatory compliance or safety—it is a strategic move that enhances the overall performance and profitability of industrial operations. For any facility operating a boiler island, prioritizing efficient ash and slag removal systems is essential for long-term success and sustainability.